Quality consists of four separate but complementary modules: system quality; product quality; SPC (Statistical Process Control); training management and safety.

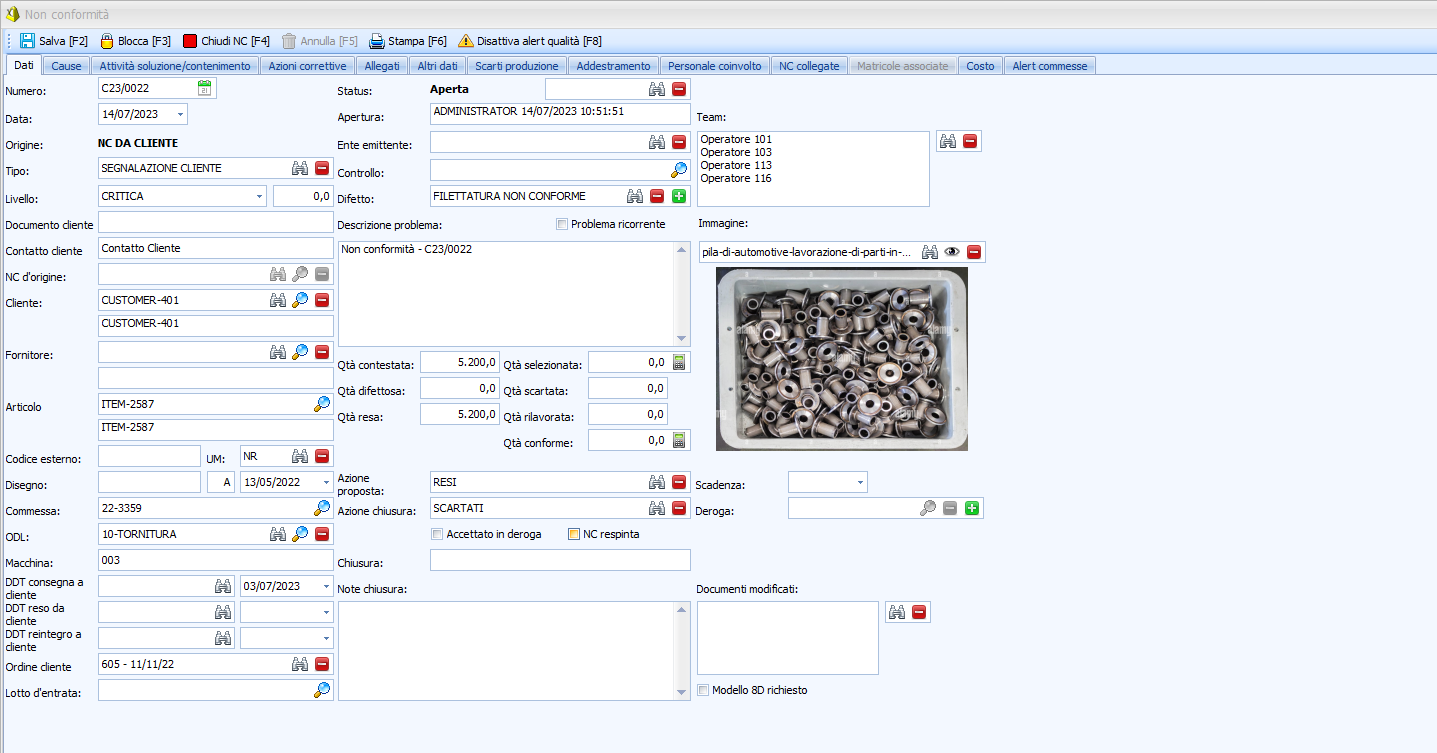

System Quality is the first module of the QUALITY suite to manage any non-conformities, corrective actions, improvement activities and supplier evaluation. With Metronomo.Net, Managing System Quality will allow you to keep all internal procedures under control and keep track of every activity carried out for each of your items, customers or suppliers. As it is perfectly integrated with the Metronomo.Net suite, via the PROCONSOLLE module you may also set up alert messages that will automatically appear as a consequence of specific events, either in the office or directly on the shop floor.

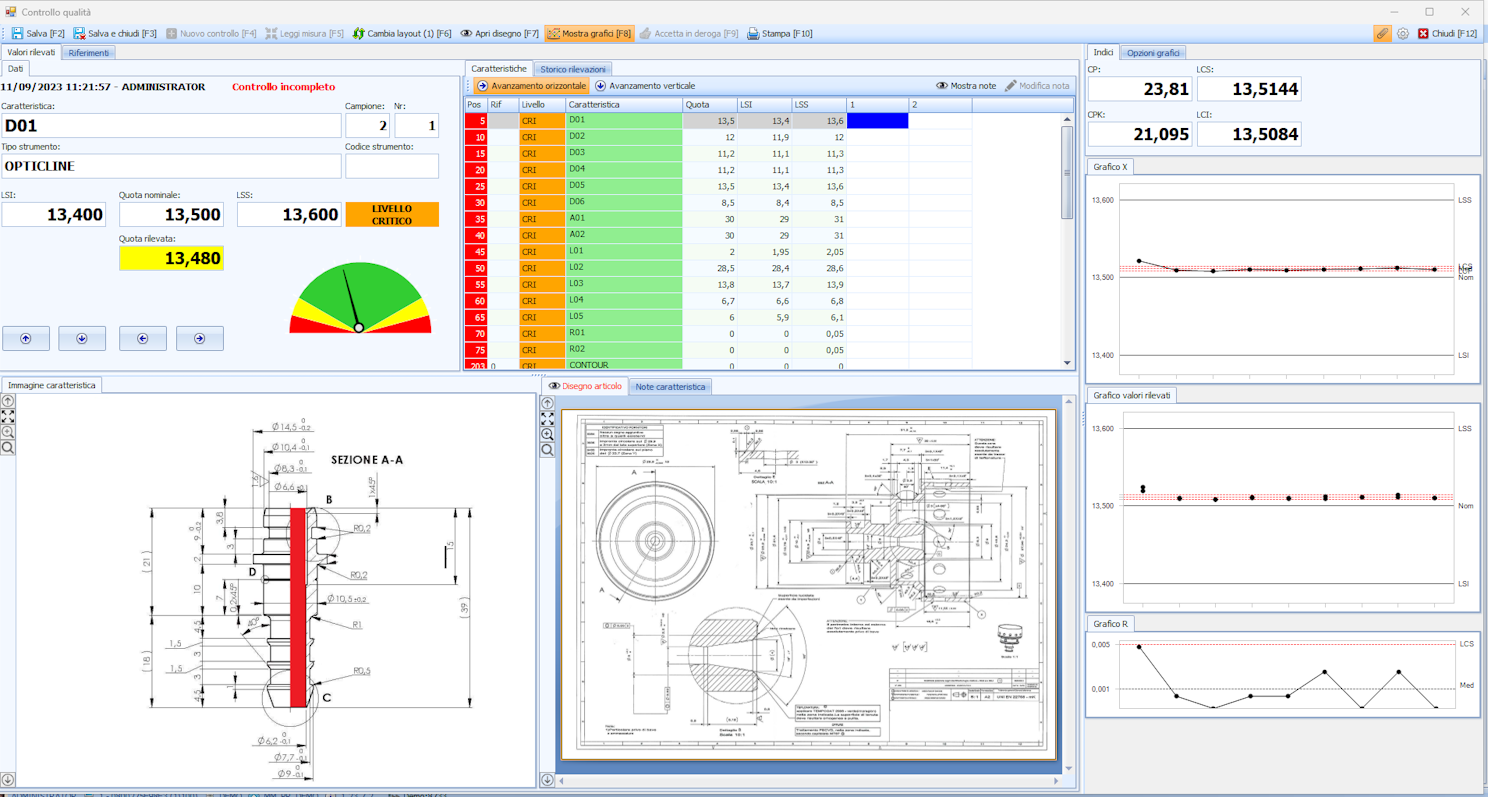

The second QUALITY module manages everything pertaining to control plans, control cycles and measuring instruments. You may create a control plan entailing one or more control cycles to be applied to each of your products. Each control cycle can be associated to a specific production step, even down to single phases, e.g. quality approvals after tooling an item. Furthermore, you may manage each measuring instrument, its master data and internal/external calibration calendars.

With the QUALITY SPC (Statistical Process Control) module you can capture the features stated in your control cycles and collect them in a control sheet. Thanks to the PROCONSOLLE module, shop floor operators may enter the taken measurements directly into Metronomo.Net, either manually or by connecting their measuring instruments to the system.

Our last QUALITY module will allow you to manage all aspects related to your employees in terms of skills, training and safety.

The QUALITY Suite is perfectly integrated with all other Metronomo.Net modules: it is the right tool to improve the management of every aspect related to the quality of your company, your products and your employees, highlighting your added value compared to other competitors to the eyes of your customers.

Advantages

Ensure the quality and recording of documents

This module has several peculiarities:

a single production-integrated module for quality management

it manages documents, such as non-conformities, corrective and improvement actions, vendor rating and archiving of all related documents

it links vision machines to the system from an Enterprise 4.0 perspective

it facilitates the creation of control plans applicable to any production stage

it records and archives all control sheets completed by the operators

it creates advanced statistics as well as control charts and CP CPK indices

it includes the implementation of SPC stations with the automatic acquisition of the measurements takenate

it manages the operators’ skills and training

it allows control alerts to be scheduled according to a certain frequency by displaying them on production terminals or directly on display boards on the shop floor.